Competitiveness in poultry farming depends on optimisation strategies at every level of the industry. Whether in the table egg or heavy chicken sectors, professionals need to adapt to improve their performance and meet market expectations. What are the most effective levers for improving efficiency in these poultry sectors?

Laying hens: taking action to extend laying cycles

1. Why increase egg-laying time?

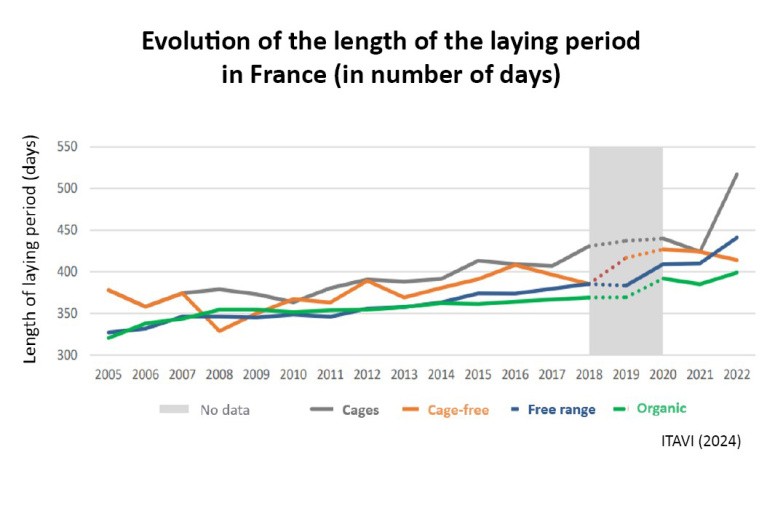

Extending the laying time of hens is a major competitive lever in the table egg production sector. Itavi has already recorded significant progress in this area. On average, alternative farms (organic, free-range, etc.) have improved their laying time by 55 days over the last 10 years in France, thanks in particular to genetic selection. The longer the hens lay, in good health, the more the farm gains. However, pullets have an incompressible, 'unproductive' period before the start of the laying cycle. So if we calculate the cost of producing eggs, including the cost of buying pullets and feed, it decreases as the culling age of the hens increases: from €1.052 to €0.861 per kg of eggs produced. However, this simulation does not take account of zootechnical risks.

Beyond the economic analysis, postponing the culling age also means increasing the rearing period for poultry, in response to societal expectations. However, care must be taken to maintain the animals in acceptable health and welfare conditions.

2. How to improve egg-laying persistence ?

Extending the laying period is an area of technical and economic progress, provided that the animals are kept in good rearing conditions. Extending the laying career of chickens has three main risks. A drop in egg-laying at the end of the batch, brittle shells and an increase in hen mortality. According to several studies, the persistence of egg-laying depends on good preparation of the animals. Particular attention needs to be paid to reaching a 'threshold' weight at the start of laying. For example, a study of 320 batches in Morocco (2014-2022) showed that pullets reached a critical weight at 20 weeks, with no possibility of catching up after that. Nutrition, which is based on 3 main pillars, plays a key role: optimising feed intake (via the quality of pellets/mash and the addition of oil), managing protein and energy intake, and supporting mineralisation.

"On the way to 500 eggs per hen! That's the target we have in mind, but we're going to have to work on it together". Glenn Panaget, Techna poultry species specialist

Heavyweight chickens: levers for competitiveness throughout the sector

1. How to maximise net yield?

Heavy chicken production is currently booming in France. Today, this segment accounts for nearly a quarter of the total, mainly for the processing industry. The yield of fillet, the noblest part of the meat, is closely scrutinised by industry professionals. What factors determine fillet yield? The first is quite simply the weight of the animal. Trials (Euronutrition 2016-2024) show a strong correlation between live weight and fillet weight, with an average increase of 240g of fillet per kilogram of live weight.

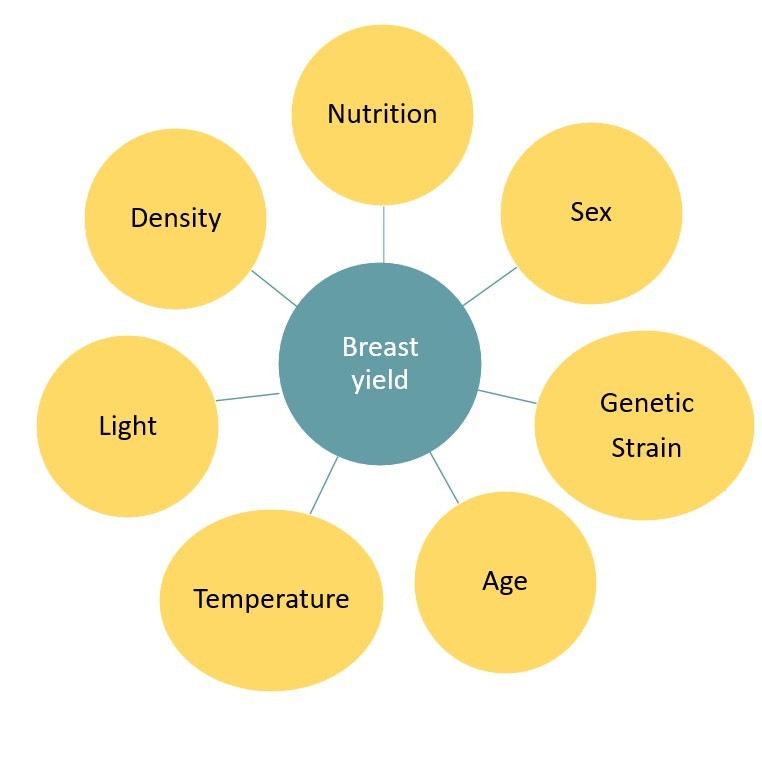

Net yield varies according to :

-

Genetics: Cobb FF chickens perform better for equivalent nutrition.

-

Sex: females have a better net yield than males.

-

Environment: light (influence of photoperiod, light intensity and spectrum). Thermal stress and increased density also penalise net weight.

-

Nutrition: a 0.05% increase in digestible lysine gives a 0.6 point gain in fillet yield under optimal conditions.

2. Sexing or all-purpose: what impact will this have on the heavyweight chicken industry?

Techna carried out an impact study comparing different heavy chicken production schemes based on a simulation for a stock of 93,000 m² of rearing buildings. The production of "all-raw" poultry is economically more advantageous, with an optimum slaughter age of 44 days. The simulation shows significant savings of €165,000. Production with sexing requires a later slaughter age (48 days). However, this study does not take into account the requirements of the downstream industry in terms of carcass homogeneity and product quality. As a result, carcass weights are more widely dispersed in 'all-cattle' production, which is hardly compatible with the slaughterhouse link.

Conclusion

For the table egg sector, longer laying times, coupled with persistent laying, are a competitive advantage.

In the heavyweight chicken sector, a number of factors play a part in determining net yield, the most important of which is nutrition. But other farming factors are also highly influential (genetics, environment, sex, etc.).

The choice of production methods for heavy chickens (weight and age at slaughter, all or sexed) has a major economic impact at the level of a producer organisation, but above all there is the question of the product's suitability for the downstream industry.

Feedia embodies Techna's range of advice and solutions in breeding techniques and precision nutrition, serving the performance of production organisations, feed manufacturers and their breeder customers.